- HOME

- Technology

- HOT process

Operations to produce LCD glass substrates are divided into “HOT” and “COLD” processes. In the HOT process, the raw materials are melted and formed into a mother glass sheet. In the COLD process, the glass sheet is cut to the size specified by the customer. In the HOT process, it is important to obtain smooth surfaces and to reduce the “defect density” (the number of defects per unit of weight) by eliminating foreign particles and air bubbles, etc. The COLD process centers on maintaining high “surface quality” free from scratches and contamination. It is necessary to appropriately control both processes to produce high-quality products.

Various kinds of powdered raw materials are fed into the melting furnace.

The powdered materials melted in the hot melting furnace are transformed into a glass melt through a vitrification reaction. The raw materials should be melted evenly so that the chemical composition in the molten glass is uniform. Since the furnace greatly affects the quality of the glass, even the slightest flaw cannot be overlooked.

Glass produces gases such as CO2, H2O, O2 and SO2 during the melting process. In this step, bubbles in the molten glass are removed and the glass melt is stirred to make it uniform.

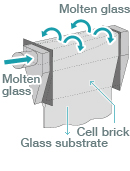

The glass melt is formed into a sheet. We use a process known as the “overflow downdraw method” to form glass sheets. This method can provide smooth surfaces because the molten glass can be cooled while it is vertically stretched without touching grass surface.

The glass sheet is slowly cooled. An optimum annealing program is necessary because rapid cooling can result in severe internal strain and other defects.

A glass substrate that has been cut to the specified dimensions is known as a “mother glass sheet.” Before feeding the products to the COLD process, the glass size and strain are checked on a monitor to determine if there are any non-conformities with the specifications.

The HOT process is automated and monitored in the control room.

The operator checks the furnace condition via a computer and monitors the production process.